On request from the result of the Omega Race, a tutorial on how the vectorization of the frontpage was made.

On request from the result of the Omega Race, a tutorial on how the vectorization of the frontpage was made.

You can find the tutorial here:

On request from the result of the Omega Race, a tutorial on how the vectorization of the frontpage was made.

On request from the result of the Omega Race, a tutorial on how the vectorization of the frontpage was made.

You can find the tutorial here:

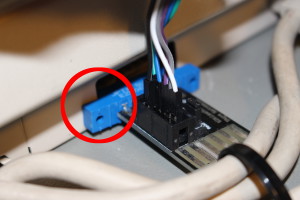

While the 1541 Ultimate 2 tape extender has a good length for the C64 and C128, it’s not long enough for the C128D, nor does it fit in the tape slot. Here’s a small hack that I’ve made to fix that.

I only had SIL headers available when I made this, so I soldered 2 x 2×5 pins together creating a 10p male-male IDC header. I had to custom make the cable as it didn’t make a 1:1 connection from the original extender cable to the tape header.

If you’re creating one like this, make note that a standard 10p IDC cable doesn’t work here as the extender cable isn’t standard connected to the header. All odd numbers on the extender cable is connected to even numbers on the IDC header, though the direction is corret. See table below for reference.

| Extender pin | IDC Cable pin |

| 1 | 2 |

| 2 | 1 |

| 3 | 4 |

| 4 | 3 |

| 5 | 6 |

| 6 | 5 |

| 7 | 8 |

| 8 | 7 |

| 9 | 10 |

| 10 | 9 |

The tape header on the extender is too wide to be plugged into the C128D. I was lazy and only connected 6 wires here, but recommended is connecting all 10 to prevent noise/stray signals (Thanks e5frog).

The tape header on the extender is too wide to be plugged into the C128D. I was lazy and only connected 6 wires here, but recommended is connecting all 10 to prevent noise/stray signals (Thanks e5frog).

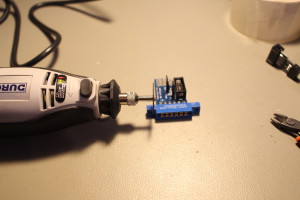

This is something a Dremmel can take care of, just cut off the additional plastic used for screws.

This is something a Dremmel can take care of, just cut off the additional plastic used for screws.

In the retro community there are a lot of different modern hardware these days, not always do they come in nice boxes.

The PCB’s can easily scratch the surface of the table, and aren’t protected against transportation etc.

Last year I made a box for my ZoomFloppy and while it was my first box, and I wasn’t all that careful trying to get it to look nice, the box is still intact.

Last night I talked to a fellow DYI guy with plenty of ideas. He got hooked by the idea of using acrylic plastic to makea box for some electronic boards. He probably have better skills, tools and whatnot than I doing this kind of things.

I’ve used Acetone to “glue” the sides together. I can say, if acetone comes onto places where it shouldn’t, let it evaporize. If you try and wipe it off it’ll smear. The acetone seems to dissolve the acrylic glass.

Here is an other example of creating a box, this doesn’t involve gluing, just acrillic spacers. This box was made by Henrik Christensen from Facebook, and used with permission here.

I must confess Henrik is more skilled than I

I must confess Henrik is more skilled than I

When I received my first A2000 it came with a SCSI drive on a SCSI controller. It came with a controller not seen much around, and it seems that the original disks are missing. I haven’t seen them on either of the 2 amiga hardware sites either.

Well the software was installed on the harddrive so I wanted to make a copy of it. The procedure I did back then is almost the same as the one I’ll show you here.

But WHY? Why take a backup of an old disk? Well sometimes the origin of the installation can be unknown, sometimes it’s known. But the disk might contain work, source codes, missing drivers like mine, or something else like Andy Warhol’s images that he did for getting to know the Paint software. Something unique that shouldn’t be forgotten or deleted.

There are some Amiga’s that has IDE drives. The procedure is the same just using an IDE controller, or USB to IDE converter instead.

For this I’m using a PC, Adaptec SCSI controller and WinUAE. Though any parallel SCSI controller that fits in your PC will do.

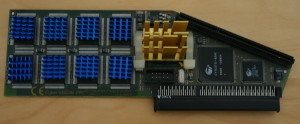

Adaptec 2940UW SCSI controller.

This disk is a 50MB Quantum Prodrive.

For other media like the IDE drives from A600/A1200 the USB to IDE converter can be used. CF cards can be used in a card reader.

A writeblocker should be used. The writeblocker prevents (accidental) writes to the disk and is recommended. These can be either software or hardware blockers. Since the hardware blockers are expensive I’m using software.

In the following video you’ll see how easy it is to dump the disk as a hdf file, which you can boot directly from WinUAE. Make a copy before you do this though.

Since yesterday I’ve been making a backup of my NAS box that contains all the scans. I got a Synology 214SE in January with 2 2TB drives configured as RAID 1 / Mirror. These days the total amount of free space is around 200Gigs. I bought 2 3TB’s for this upgrade and while the backup takes time I can’t work with scans.

So while I’m taking a backup I might as well make a nice little post.

I’ve previously had some issues in adding a GOTEK drive into my external drive enclosures for the Amiga. So I’ve had this project shelved. Today I took one of the other enclosures and tried that. Yes this one works.

For you who don’t know what a GOTEK drive is, I’ll make a short explanation of it. It’s a floppy to usb emulator. You can use a USB drive and attach it to this device which is then plugged to the floppy controller of the computer, sewing machine, keyboard etc.

Hervé Messinger made a guide and a firmware so it can be used in the Amiga. See his project site: http://cortexamigafloppydrive.wordpress.com In the current firmware (1.05) there are some qirks that still needs fixing, i.e. cannot format a disk, nor use track copy applications like X-Copy.

The GOTEK drive can be aquired for around $19 on eBay (price update 2015-02-21).

After replacing the floppy drive with the GOTEK I noticed how dirty the enclosure was.

Foamclean to the rescue. The pictures will speak for themselves.

For all support about the GOTEK drive please ask in Hervé’s site.

For all support about the GOTEK drive please ask in Hervé’s site.

If you live in Denmark, I can assist in flashing the firmware if required, but I’d suggest that you learn to do that, so you can upgrade the drive when a new firmware comes out.

No it really isn’t that hard flashing this yourself.

And a word of caution. Remember that Hervé was the one who created this firmware. He get’s nothing from any of the guys selling these drives preflashed with the Amiga firmware.

There are quite a few guides on the net, how to replace an existing rechargable battery with a coin battery. Targeted mostly for big box Amiga’s and accelerators, but this can also be used for other similar replacements.

You all know it’s neccessary to change the rechargable battery. If you don’t I’ll tell you why: the battery contains what is commonly mentioned as battery acid, though for these batteries it’s base. Regardless it corrodes the electronics so the battery needs to be removed and the affected area needs to be neutralized. The battery can be removed by using cutters (be careful not to damage the PCB) or just desoldering it. A wash with either lemon juice or vinegar can be neccessary if the battery has leaked. Just drop some lemon juice/vingar and scrub with i.e. a toothbrush. Remove the liquid and wash with either water or isopropyl alcohol.

After removal, some area has been damaged, but luckily not much.

After removal, some area has been damaged, but luckily not much.

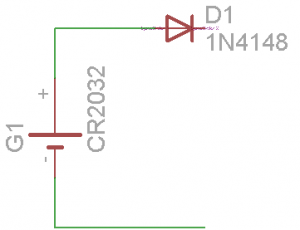

If you’re going to replace with a coin battery like the CR2032, which are quite common these days, you’ll need to add a diode to prevent recharging of the battery with 5v.

The drawing below should explain it all. The schematic on the new battery.

The schematic on the new battery.

How it needs to be soldered, plus is to the right and minus is to the left.

How it needs to be soldered, plus is to the right and minus is to the left.

Some diode theory 101:

Notice the black ring on the diode, this should be to the farthest side away from the coin battery. Notice the same “ring” on the schematic, that lone vertical dash, thats how you identify which is which. The left side here on the drawing is called anode, and the right side is called cathode. If you turn the symbol 90 degrees CCW, the symbol almost looks like an A, and from the other side it looks like a vertically-mirrored K (just pronaunce the cathode as kathode).

The cathode blocks all the voltage (to a certain degree) that lies on the kathode, whereas the voltage that lies on the anode passes on to the cathode, though loosing around 0.6-0.7 volts.

This way we prevent 5v that’s used to charge the old battery to also charge the non-rechargeable CR2032 battery.

It’s hard to see on this pic, but the black wire extended from the red is a diode all wrapped in a shrink tube. The solder pads here have been dripped with hotglue to prevent shorts.

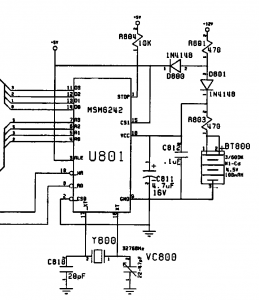

On this schematic taken from the Amiga 2000 schematics, the battery we’re replacing is in the lowest, rightmost corner (BT800). Looking up the Datasheet of the MSM6242 real time clock, the lowest voltage for battery backup is 2v. So with the CR2032’s 3.3v minus the 0.7v (= 2.6v) the battery supply is still enough to sustain the real time clock.

On this schematic taken from the Amiga 2000 schematics, the battery we’re replacing is in the lowest, rightmost corner (BT800). Looking up the Datasheet of the MSM6242 real time clock, the lowest voltage for battery backup is 2v. So with the CR2032’s 3.3v minus the 0.7v (= 2.6v) the battery supply is still enough to sustain the real time clock.

Components used: CR2032 socket, 1n4148 diode.

You can use most regular diodes like the 1n4141.

Update: 2019-04-02

Araranet has created a small pcb which works as a drop in replacement for the old barrel batteries, The A4000battkit, ready for sending to pcb companies like jlcpcb.com.

After using my Amiga 4000D with CyberstormPPC and CyberVisionPPC for several hours, the enclosure got quite warm to the touch. This made me a quite anxius as I don’t want the hardware to die because of heating.

I found out that the PSU fan pulled air from the back into the enclosure, I wonder if that was by design or someone having flipped the fan in the wrong direction. This needed turning so it would transfer the hot air from inside through the PSU to the outside of the enclosure. While at it, I could improve the flow a little, and reduce the noise of the fan. I don’t want to use a lower voltage with a lower fan speed, this is due to I prefer to keep my hardware cool and in good order.

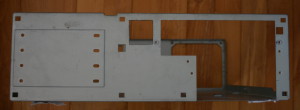

Taking evertything apart is easy, so I find no need to explain how to do that. The before picture of the PSU. You can vaguely see my pencil marks where to cut.

Taking evertything apart is easy, so I find no need to explain how to do that. The before picture of the PSU. You can vaguely see my pencil marks where to cut.

Time to get busy with a dremel and a cut-off wheel.

Time to get busy with a dremel and a cut-off wheel.

The area where I can pull air from the front isn’t that large, I still want to keep the holes for the different parts, like to fasten the external drive bay, putting wires through the hole, and the front bezel in the middle top. The dremel is a great tool for this, and mine isn’t even an original one, but something cheap bought in an Aldi store.

The dremel is a great tool for this, and mine isn’t even an original one, but something cheap bought in an Aldi store.

Time to add heatsinks to the CyberVision. I recieved this one with the GPU mounted heatsink, no need in changing that. But I added the heatsinks on the ram chips, these I got off eBay. I added the heatsinks long before this project, and eventually that was a mistake as they are mounted in the wrong direction for best cooling. Oh well, they work better than with no heatsinks.

Time to add heatsinks to the CyberVision. I recieved this one with the GPU mounted heatsink, no need in changing that. But I added the heatsinks on the ram chips, these I got off eBay. I added the heatsinks long before this project, and eventually that was a mistake as they are mounted in the wrong direction for best cooling. Oh well, they work better than with no heatsinks.

For some reason I didn’t take a picture of mounting a heatsink on the 68060 cpu. I used an old heatsink from a 80486 cpu, added compound paste, wiped off the corners and used LocTite glue on those corners. I also added some paste to the PPC CPU before reattaching the heatsink and it’s fan.

For some reason I didn’t take a picture of mounting a heatsink on the 68060 cpu. I used an old heatsink from a 80486 cpu, added compound paste, wiped off the corners and used LocTite glue on those corners. I also added some paste to the PPC CPU before reattaching the heatsink and it’s fan.

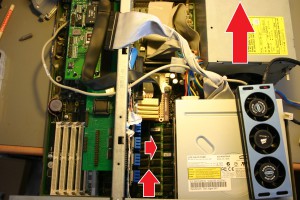

I had a stick of fans from some Corsair ram for my PC, these I soldered a molex connector and gave it 7v (using 5v as ground and 12v as reference). The flow of air is marked with the arrows. In through the front, down on the Cyberstorm ram (you might be able to spot the heatsink on the 68060 CPU if you click on the image to see the full size), and out through the PSU.

I had a stick of fans from some Corsair ram for my PC, these I soldered a molex connector and gave it 7v (using 5v as ground and 12v as reference). The flow of air is marked with the arrows. In through the front, down on the Cyberstorm ram (you might be able to spot the heatsink on the 68060 CPU if you click on the image to see the full size), and out through the PSU.

The (almost) finished project. It’s not perfect, but it works pretty well. I’m still looking for a better way to attach the ram coolers, acryllic glass comes to mind. After several hours of usage the enclosure is now still cool to the touch, only the area around the PSU is warm, but not as warm as it was before.

The (almost) finished project. It’s not perfect, but it works pretty well. I’m still looking for a better way to attach the ram coolers, acryllic glass comes to mind. After several hours of usage the enclosure is now still cool to the touch, only the area around the PSU is warm, but not as warm as it was before.